MBB C 1500 SZ

photo_panel:

- For steep attachment with extremely short vehicle overhangs

- 1,500 kg lifting capacity with 1,000 mm load distance

- 2,000 kg lifting capacity with 750 mm load distance

- Four-cylinder lifting mechanism with low installation depths and four different lifting arm lengths

- Design with aluminium or steel platform

- Large selection of special equipment available

Specyfikacja:

| Specyfikacja | Diagram | ||

|---|---|---|---|

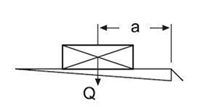

| Udźwig | 1500.0 kg | a (mm) | Q (kg) |

| Belka nośna | 180 x 180 mm | 1000 | 1500 |

| Układ hydrauliczny | 2 x siłownik podnoszący / 2 x siłownik zamykający | 1200 | 1250 |

| Platform overlap with floor | - 63 mm | 1500 | 1000 |

| Rostaw ramion podnoszenia /Długość ramion | 1300 mm | 1850 | 800 |

| Środek ciężkości – ładunek na środku podestu | 1000.0 mm | 2400 | 600 |

| Środek ciężkości – ładunek po jednej stronie | Central, 50 % pełnego obciążenia na stronę |

|

|

| Kąt pochylenia podestu | +90° do -10° degrees | ||

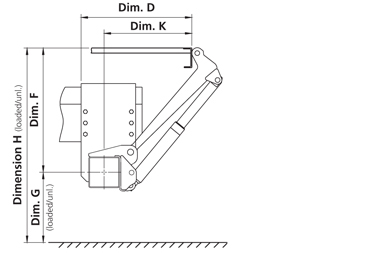

| Dimensions | ||||||

|---|---|---|---|---|---|---|

| Lift arms (in mm) | 750 | 800 | 850 | 950 |

|

|

| H (max.) | Loading height unloaded | 1340 | 1416 | 1505 | 1657 | |

| H (min.) | Loading height loaded | 1127 | 1165 | 1204 | 1281 | |

| F (max.) | Middle of main beam to upper edge of loading floor | 858 | 904 | 967 | 1061 | |

| K (min.) | at dimension F (max.) | 413 | 434 | 410 | 444 | |

| D (min.) | Installation space (min.) | 563 | 584 | 560 | 594 | |

| D (max.) | Installation space (max.) | 752 | 785 | 816 | 880 | |

| F (min.) | 742 | 780 | 819 | 896 | ||

| K (max.) | at dimension F (min.) | 602 | 635 | 666 | 730 | |

| WEIGHTS | |||

|---|---|---|---|

| Platform type | Width (mm) | Height (mm) | Dead weight (kg) |

| alu | 2500.0 | 1850.0 | 547.0 |

| alu | 2500.0 | 2100.0 | 569.0 |

| stell | 2500.0 | 2009.0 | 735.0 |

| stell | 2500.0 | 2109.0 | 785.0 |

| The specified weights apply to the lightest platforms of the corresponding height. Dimensions may vary. Subject to technical changes, errors and translation mistakes | |||

opcje:

1.lifting unit with KTL-coating + power

2. steel platform

3.aluminium platform with R13

4.roll stops

plusy:

{"1": {

"x":102,

"y":122,

"mouseover":"Ramp angle of platform",

"onClickHtml":"</br></br>We achieve the lowest ramping angle due to our special connection of the head to the platform."

},

"2": {

"x":182,

"y":271,

"mouseover":"ELECTRONIC CONTROL",

"onClickHtml":"</br></br>The uniqueness of our control is the patented sensor system. Herewith we are able to read out and analyse all directions and speeds of motion."

},

"3": {

"x":114,

"y":265,

"mouseover":"LIFTING UNIT WITH KTL-COATING",

"onClickHtml":"</br></br>All our lifting units are KTL-coated and reach 1000 hours in the salt-spray-test according to EN ISO 12 944-2 CSM."

},

"4": {

"x":144,

"y":252,

"mouseover":"HYDRAULIC CYLINDERS",

"onClickHtml":"</br></br>One of our core competences is the cylinder manufacturing in our own plant. Here we produce about 65.000 cylinders per annum. A burst pipe protection is achieved by integrated current regulating valves."

},

"5": {

"x":203,

"y":231,

"mouseover":"CONTROL BOX WITH INTERIOR LIGHT",

"onClickHtml":"</br></br>The ergonomically shaped control box has an interior light as standard.</br>"

}

}

waga:

39.00

tagi:

ca